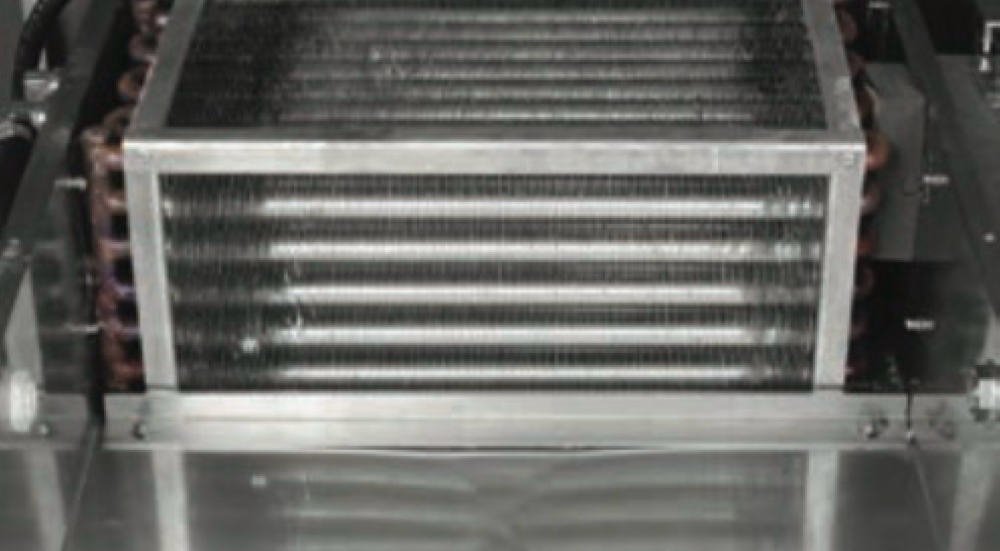

All in stainless steel 18/10 AISI 304. The washing tunnels are composed of different modules, which allows for disassembly to facilitate entry, and then proceed with assembly easily once located in the workplace. The entire tunnel is made with a double wall, including guillotine doors, which reduces noise and heat loss. The tanks are stamped, with rounded edges to facilitate cleaning. Additional modules include modules for angled pre-washing, angled drying modules, intermediate neutral modules, or neutral entry zone modules, detergent and rinse aid dispensers, etc. The filter is composed of a flat and inclined surface for the drainage of solid waste and a basket that collects it. Easily removable for emptying and cleaning. They allow an entry height of 450 mm, for baskets of 500x500, allowing washing trays, GN containers, and other utensils. The basket is dragged with side guides, facilitating cleaning. The teeth that move the baskets are made of thick stainless steel. They are reversible, which allows changing the entry or exit direction by performing simple operations. However, we recommend specifying the direction of travel when placing the order, so it will come factory-prepared. The speed of basket advancement is electronically regulated by a frequency converter and is controlled from the control panel. Each of the modules for pre-washing/washing/rinsing and drying starts and stops independently, only if there is really a basket inside. This system improves energy consumption. Control is carried out through an electronic control panel, with a multifunction screen, a 4-digit LED. It has 4 touch buttons to program all functions, provide information, select programs, etc. With USB connection. The temperature of the feed water is recommended to come from a heater, from 40 to 60 °C, as indicative production data are based on this. If the water enters from 15 to 40 °C, production will be lower and energy consumption higher. It also depends on whether you have the heat recovery module. Comes with 2 baskets (multipurpose and for plates) and 1 cutlery cup. With adjustable stainless steel legs, 200 mm. Pre-wash module with a length of 820 mm, equipped with a 70-liter tank and a washing system with 3 arms and 36 nozzles, with a double-flow pump, 1.5 kW power. Washing/rinsing module with a length of 1150 mm, has a 70-liter tank, and a washing system with 5 arms and 60 nozzles, with a double-flow pump, 2.7 kW. The temperature management system, with water heating or cooling, is electronically controlled. A constant feed pressure of 2 to 4 bar is required.